Krisry International offer a comprehensive range of ISO1161 Corner Castings available as Steel ISO Corner Fittings, Aluminum Corner Fittings and Stainless Steel Corner Castings. We offer Standard ISO1161 corners for 8’-0“ wide, USA Inland Corners for 8’-6” wide Containers and European fittings for 2.5M wide containers.

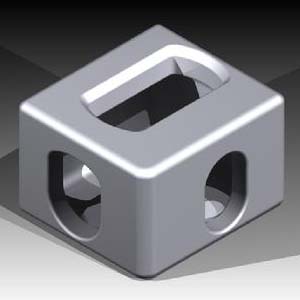

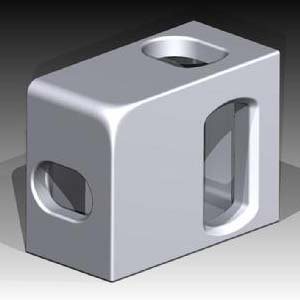

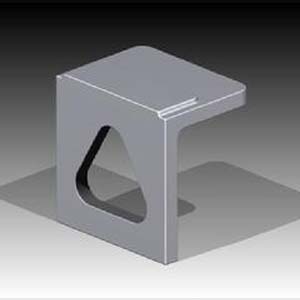

ISO CORNER CASTINGS

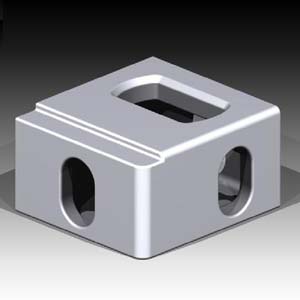

BLR 20100 & BLR 20000

Standard ISO type container corner castings to suit all requirements. Made in accordance with ISO 1161/BS 3951 and Lloyds Register Guidance Note A — Also available in Stainless Steel.

Type BLR 20100

Top Container Corner Fitting

Weight: 10.5 kg/23 lbs

Download Technical Details PDF

Type BLR 20000

Bottom Container Corner Fitting

Weight: 10.5 kg/23 lbs

Download Technical Details PDF

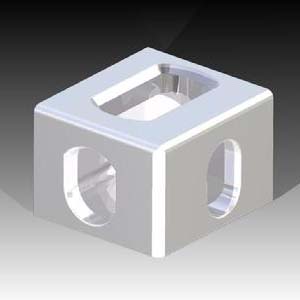

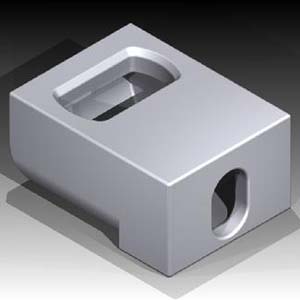

ALUMINIUM CONTAINER CORNER FITTINGS

BLR 4035 & BLR 4045

Container corner fittings made to Independent Classification Society Approved Standards. Certification can be provided by: Lloyds Register of Shipping or Bureau Veritas. Manufactured from high-strength extruded aluminium.

AL-ZN5-Mgl with following mechanical properties:

Tensile strength = 350N/mm² (34KP/mm²)

Tensile proof stress = (at 0.2%) 290N/mm² (28KP/mm²)

Elongation % 5.65 x √area = 10%

Type BLR 4035

Top Container Corner Fitting

Weight: 4.5 kg/10.0 lbs

Download Technical Details PDF

Type BLR 4045

Bottom Container Corner Fitting

Weight: 4.5 kg/10.0 lbs

Download Technical Details PDF

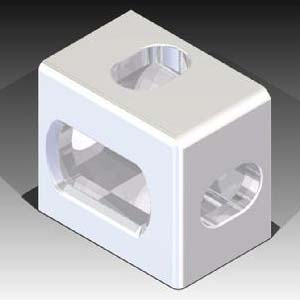

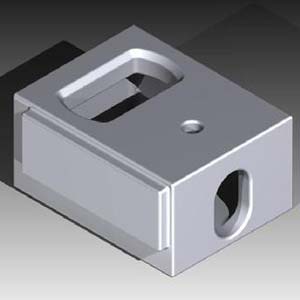

ALUMINIUM CONTAINER CORNER FITTINGS

BLR 1069 & BLR 1070

Container corner fittings designed for safe working load of 3250 KG and are manufactured to dimensionally comply with ISO 1161-1984. For lightweight military shelter & industrial use. Weldable aluminium alloy casting.

-

For lightweight military shelter and industrial use.

-

High strength weldable aluminium alloy casting.

-

Designed for Safe Working Load of 3250 kg. (7150 lbs.)

-

BS149OLM25TF

Type BLR 1070

Upper Container Corner Fitting

Weight: 8.8 lbs/4.0 kg

Download Technical Details PDF

Type BLR 1069

Lower Container Corner Fitting

Weight: 8.8 lbs/4.0 kg

Download Technical Details PDF

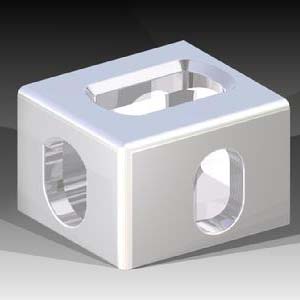

USA INLAND CONTAINER CORNER CASTINGS

BLR 1028 & BLR 1029

Container corner castings to suit 8′ 6″ wide Dry Freight, Reefer and Tank containers. Apertures at ISO series 1 container positions and series 1 container sizes. Suitable for 48′ and 45′ long containers. These products are made from special steel designed for low temperature working at -40°C as standard. For 8′ 6″ wide Dry Freight, Reefer and Tank containers.

-

To suit 8′ 6″ wide containers.

-

Apertures at ISO series 1 container positions.

-

Apertures at ISO series 1 container sizes.

-

Suitable for 48′ and 45′ long containers.

-

Other dimensions may be supplied, on request, to meet your requirements.

-

Drain holes for excess water. (Lower fitting only)

Type BLR 1029

Upper Container Corner Fitting

Weight: 33.7 lbs/15.3 kg

Download Technical Details PDF

Type BLR 1028

Lower Container Corner Fitting

Weight: 33.4 lbs/15.2 kg

Download Technical Details PDF

USA INLAND UPPER & LOWER INTERMEDIATE CONTAINER CASTING

BLR 1032 & BLR 1540

Container castings to suit 8′ 6″ wide containers. Apertures at ISO series 1 container positions and series 1 container sizes. Suitable for 40′ long and over containers. These products are made from special steel designed for low temperature working at -40°C as standard. Castings for 8′ 6″ wide Dry Freight, Reefer and Tank containers.

-

To suit 8′ 6″ wide containers

-

Apertures at ISO series 1 container positions

-

Apertures at ISO series 1 container sizes

-

Suitable for 40′ long and over containers

-

Other dimensions may be supplied, on request, to meet your requirements

Type BLR 1032

Upper Intermediate Container Corner Fitting

Weight: 29.3 lbs/13.3 kg

Download Technical Details PDF

Type BLR 1540

Lower Intermediate Container Corner Fitting

Weight: 35.3 lbs/16.0 kg

Download Technical Details PDF

ISO CONTAINER CORNER FITTINGS

BLR 91400 & BLR 91300 (German)

These container corner fittings products are made from special steel designed for low temperature working at -40°C as standard.

Made in accordance with ISO 1161/BS 3951 and Lloyds Register Guidance

Note A: Also available in Stainless Steel

Type BLR 91400

Upper Container Corner Casting

Weight: 25.3 lbs/11.5 kg

Download Technical Details PDF

Type BLR 91300

Lower Container Corner Casting

Weight: 26.0 lbs/11.8 kg

Download Technical Details PDF

ISO EXTENDED TOP APERTURE CASTING

BLR 263 & BLR 430

Container Casters for Fixed or Folding End Flatrack

- Extra Length Top Aperture

- Longer aperture allows for quick spreader location and helps to prevent damage. These products are made from special steel designed for low temperature working -40°C as standard

- Classification Society approved

- Longer aperture allows quick spreader location and helps to prevent damage

NOTE: End aperture MUST be blanked off prior to container going into service, to prevent ‘hook lifting’. (Ref. ISO 1496-5)

Note A: Also available in Stainless Steel

Type BLR 263

Extended Aperture Container Casting

ISO + 10mm = 134mm

Weight: 23.3 lbs/10.6 kg

Download Technical Details PDF

Type BLR 430

Extended Aperture Container Casting

ISO + 20mm = 144mm

Weight: 24.4 lbs/11.1 kg

Download Technical Details PDF

LOWER CORNER CONTAINER CASTING

FOR 2.55 M WIDE CONTAINERS

BLR 4450

These corner container casting products are made from special steel designed for low temperature working at -40C as standard. These products are made from special steel designed for low temperature working at -40°C as standard.

- To suit 2.55 meter wide Dry Freight, Reefer, and Tank containers

- Apertures at ISO Series 1 container postitions

- Clearance for trailer lip

- Also available in Stainless Steel and Aluminum

Type BLR 4450 (LOWER CORNER CONTAINER CASTINGS)

Weight: 36.6 lbs/16.6 kg

Download Technical Details PDF

ALUMINIUM CONTAINER CORNER FITTINGS

BLR 4125 & BLR 4425

(Overland Type)

These container corner fittings are designed, manufactured and tested to meet the requirements of ISO 1161.T

Made to Independent Classification Society Approved Standards.

Certification can be provided by: Lloyds Register of Shipping and Bureau Veritas.

These corner fittings are manufactured from high-strength extruded aluminum.

Mfg. from AL-ZN5-Mgl with the following mechanical properties:

Tensile strength = 350N/mm² (34KP/mm²)

Tensile proof stress = (at 0.2%) 290N/mm² (28KP/mm²)

Elongation % 5.65 x √area = 10%

Type BLR 4125

Bottom container corner fitting

Weight: 11.2 lbs/5.0 kg

Download Technical Details PDF

Type BLR 4425

Bottom container corner fitting

Weight: 11.2 lbs/5.0 kg

Download Technical Details PDF

EUROPEAN OVERLAND CONTAINER CORNER FITTINGS

BLR 541 & BLR 542

These container corner fittings are made from special steel designed for low temperature working at -40C as standard. For 2.5 metre wide Dry Freight, Reefer and Tank containers.

Type BLR 541

Upper container corner fitting

Weight: 33.9 lbs/15.4 kg

Download Technical Details PDF

Type BLR 542

Lower container corner fitting

Weight: 31.7 lbs/14.4 kg

Download Technical Details PDF

EUROPEAN OVERLAND CONTAINER CORNER FITTING

BLR 607

These container corner fittings are made from special steel designed for low temperature working at -40C as standard. For 2.5 meter wide Dry Freight, Reefer and Tank containers.

Type BLR 607

Lower Container Corner Casting

Weight: 32.3 lbs/14.7 kg

Download Technical Details PDF

EUROPEAN OVERLAND CONTAINER CORNER FITTINGS

BLR 1012 & BLR 1013

These container corner fittings are made from special steel designed for low temperature working at -40C as standard. For 2.5 metre wide Dry Freight, Reefer and Tank containers.

Type BLR 1012

Upper Container Corner Casting

Weight: 34.4 lbs/15.6 kg

Download Technical Details PDF

Type BLR 1013

Lower Container Corner Casting

Weight: 31.5 lbs/14.3 k

Download Technical Details PDF

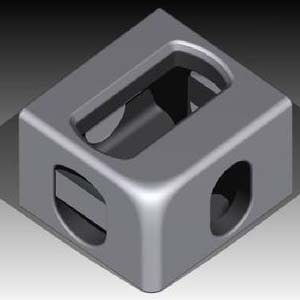

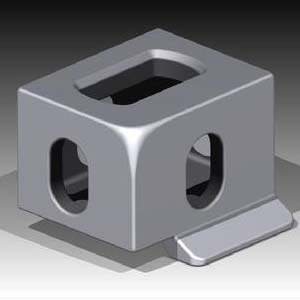

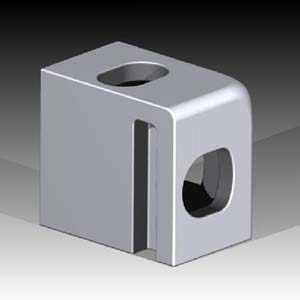

MINI BOX CONTAINER CORNER FITTING

BLR 1073

Container corner fittings and casters to suit off-shore and mini containers. To suit angled or vertical lift slings. Flush walls allow cost effective manufacture by using square cut rails and posts. Designed for low temperature working at -40C as standard.

- To suit off-shore and mini containers.

- To suit angled or vertical lift slings.

- Flush walls allow cost effective manufacture by using square cut rails and posts.

- Flush walls allow simple repair of container frames.

- One piece casting overcomes inconsistencies with weld fabrication designs.

- Design allows stacking of containers.

Type BLR 1073

Lifting hole to suit up to 30mm diameter “D” shackle

32.5mm boss width

Safe working load 3250 kg

Weight: 9.2 lbs/4.2 kg

Download Technical Details PDF

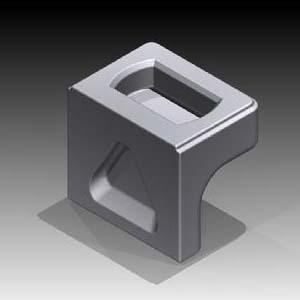

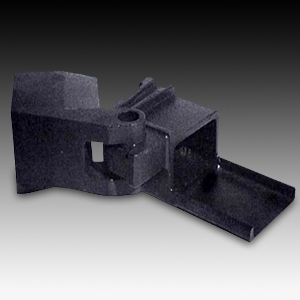

MINI BOX CONTAINER CORNER FITTING

BLR 4620

Container corner fittings and casters to suit off-shore and mini containers. Designed for both square boxes and width to length raio of 1:1.25. Safe working load (per set of 4) is 20 tons. These products are made from special steel designed for low temperature working at -40°C as standard.

- To suit off-shore and mini containers

- Designed for both square boxes and width to length ratio of 1:1.25

- Safe working load of 20 tons (per set of 4)

- One piece casting overcomes inconsistencies of fabricated designs

- Robust design ensures long life

- Design allows stacking of containers

Type BLR 4620

Safe working load: 5 tons

Weight: 12.5 lbs/5.7 kg

Download Technical Details PDF

HI-CUBE INLAND FITTING

BLR 4238 & BLR 4239

Lower intermediate container castings. These products are made from steel designed for low temperature working at -40C as standard. To suit 102 3/8″ wide containers. Ultra low profile for increased uninterrupted load space.

Type BLR 4238

Lower Intermediate Container Casting

Dual twistlock apertures to interface with chassis twistlock and stacking twistlock locations.

Weight: 33.50 lbs/15.2 kg

Download Technical Details PDF

Type BLR 4239

Upper Intermediate Container Casting

– To suit 102 ³⁄8″ wide containers.

– Ultra low profile for increased uninterrupted load space.

– Upper side aperture profile suits latest pin-lift type handling equipment.

Weight: 29.3 lbs/13.3 kg

Download Technical Details PDF

HI-CUBE INLAND FITTING

BLR 4240 & BLR 4299

These container castings products are made from steel designed for low temperature working at -40C as standard. To suit 102 3/8″ wide containers. Ultra low profile for increased uninterrupted load space.

Type BLR 4240

Lower Container Castings

Weight: 25.72 lbs/11.67 kg

Download Technical Details PDF

Type BLR 4299

Upper Intermediate Container Castings

NOTE: Suitable for containers designed for upper stack position only.

Weight: 23.47 lbs/10.65 kg

Download Technical Details PDF

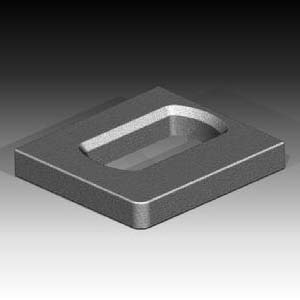

TWISTLOCK APERTURE CONTAINER CASTINGS

BLR 1035

Container castings esigned for fabrication into demountable body systems. Standard ISO aperture to suit all types of twistlock head. Full ISO corner casting footprint.

Type BLR 1035

- Designed for fabrication into demountable body systems

- Standard ISO aperture to suit all types of twistlock heads

- Full ISO corner footprint

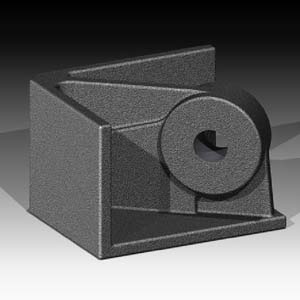

WELD SEAL DOOR HINGE

BLR 500

Container door hinge complete with heat-reacting heat-sealant. Automatically seals well known container door corrosion trap behind the hinge. Sealant expands up to 100% during welding.

Container door hinge complete with heat-reacting sealant.

Type BLR 500

This hinge offers the user the following important advantages:

- Automatically seals well known container door corrosion trap behind the hinge.

- Sealant expands up to 100% during welding.

- Self-lubricating nylon bushings give smooth door operation.

- Available in self color, galvanized and electroplate surface finish.

- Mounting brackets and stainless steel hinge pin can be supplied extra.

- Worldwide patents.

FLUSH FIT HIGH DOOR ACCESS

BLR 522

For use on all ISO Series 1 containers. Classification Society Approved. International patents pending. Allows increased door height up to 32mm. Nine high stacking capability.

Container door hinge complete with heat-reacting sealant.

Type BLR 522

For use on all ISO Series 1 containers. Classification Society Approved. International patents pending.

- Allows increased door height up to 32 mm

- Nine-high stacking capability

- Allows reduced welding by up to 30%

- Reduction of time process – header cut square without notching

- Weld preparations on the casting

- Reduction of repair costs – header removed with straight cut

OPEN TOP SWINGING HEADER

BLR 592/593

For use on all 20 foot and 40 foot open top containers top lashed, canopy type. Meets ISO requirements. Easy interchangeable components. Supplied with intergral weather seal.

Type BLR 592/593

This offers the user the following important advantages:

- For use on all 20 foot and 40 foot open top containers top lashed, canopy type

- Meets I.S.O. requirements

- Easy interchangeable components

- Supplied with integral weather seal

- Pivots from either end

- Worn or damaged seals quickly replaced

- Compact unit giving maximum door aperture

- Load transfer through pivot bosses and transfer pads to ensure easy pin removal

- Built in labyrinth for efficient sealing against weather

***Please note, not all of our products are listed on our website.

To inquire about a custom product, or a part that is not shown,

please contact our main office, or send us an email***